- 1. Shockoe Denim

- 2. Shockoe Denim

- 3. Shockoe Denim

- 4. Shockoe Denim

- 5. Shockoe Denim

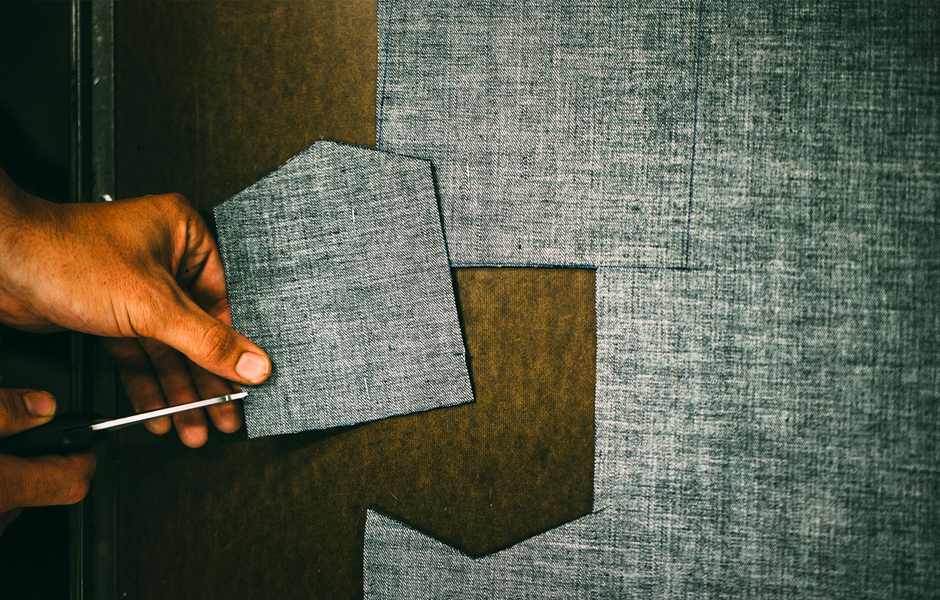

So what makes Shockoe Denim stand out from the hundreds of other brands out there? When making jeans, they believe it’s easy to achieve 90 percent. But the last 10 percent can only be obtained through time, sweat and dedication, and they are fanatical about getting to that full 100. Shockoe’s handmade denim has more volume than the average jean because they don’t go through folders during production that can flatten the garment and stress the seams. They finish their inseams with high-density serging at five times the normal stitch count so they don’t snag and sprout holes in unsightly places. And their waistbands are made with two pieces instead of one to stand up against the stress of everyday wear. And if all of Shockoe’s meticulous manufacturing isn’t enough, they offer free repairs for the life of the jean just in case. Shockoe has a fit for everyone from classic straight to slim and tapered for a modern fit.

But if you’re really looking for the perfect match, they also offer made-to-measure and bespoke jeans from their store in Richmond or through custom denim events hosted by stockists. To learn more and to shop, visit shockoedenim.com.